Our facilities are in a state of constant controlled rapid growth. We have the abilities to rapidly procure and implement facilities and equipment to support your project. Amongst the several facilities recruited and maintained by Phoenix, the main building currently in use by all departments is approximately 114,000 sq. ft., with 14’ ceilings, and with a 4,200 Amp 3 Phase electrical service.

114,000 square foot main building with up to 14' ceiling height with 4,200 amp three phase electrical service

8,000 square foot special processes facility (Heat Treat, Water Jet, CNC Machining, & Stretch Forming)

Clean Room 1

Clean Rooms:

40' X 60' X 12' high Class 1,500,000 clean room for machining honeycomb and other items in a controlled atmosphere

40' X 40' X 9' high Class 100,000 clean room with HEPA filters

25' X 85' X 12' high Class 100,000 clean room

Large Autoclave 13' diameter x 42' long

Autoclaves:

6' Dia x 13' Long 650 F, 220 PSI

3'9" Dia x 6'6" Long 700 F, 350 PSI

13' Dia x 42' Long 350 F, 150 PSI

40' X 25' X 14' high paint booth with water sprinklers and filter system

Paint Booths:

40' X 25' X 14' high paint booth with water sprinklers and filter system

12' X 12' X 7' high primer application paint booth and curing oven

16' X 24' X 8' high paint booth

Spot Welder

Our newest spot welder is a Sciaky Three Phase Welder. It’s 10”x 36” throat, touch weld controls, and water cooling make it an ideal choice for repair and manufacturing support. This PMCO.2STIC-100-36 type machine is a 460 V, 60 Hz, 3 phase welder with 63,000 Peak Sec. Amps at 5 cycles. This machine is co-located near our Phosphoric Acid Anodizing and cleaning lines. This allows for fast and effective surface preparation and enables superior welds. Our Material Test Lab also supports our spot welding activities by performing testing and weld inspections to ensure that each part’s welding process is meeting or exceeding customer expectations.

Media Blaster (Surface Preparation):

There are 4 Media Blasters throughout the shop with capabilities of blasting components up to 4’ in diameter. We also have a “Walk In” Blast Media Booth that has the capability of blasting components up to 15’ x 20’.

Metal Bond Preparation:

Alkaline Cleaner

Acid Etch

Phosphoric Acid Anodize (PAA)

Deionized water generation paint

Evaporator for waste management

Phosphoric Acid Anodize Line (PAA)

12' X 12' X 7' primer booth and honeycomb expander

Honeycomb cutters and expanders:

Honeycomb expander 5' X 12'

Honeycomb cutter 5' X 12"

Prepregnated Adhesive Cutting Table

High speed cutting table with programming capabilities

250 ton hydraulic press

Compression Molding Presses: 7.5 ton overall platen size 15" X 20 " down-acting lab press 30 ton, overall platen size 15" X 15" up-acting Wabash Self-contained hydraulic press 250 ton, overall platen size 52" left to right X 25" front to back 39" up-acting Wabash Self-contained hydraulic press.

12' shear

10' 60 ton brake

Machine Shop Includes:

Manual Machines

3 Knee Mills

2 Lathes

Surface Grinder

Belt Sander

2 types of Band Saws

Cold Saw

3 Welders

Baileigh 50 Ton Shop Press

2 Bench Grinders

Drill Press

Benchtop Arbor Press

2 Granite Surface Tables

HAAS ST-25Y CNC Lathe - Rigid machine, with live tooling for superior cutting performance on everyday jobs and production jobs.

HAAS VM3 & VF-2YT CNC Mills - Vertical machining center that is designed for high-precision, such as mold making and tool and die work.

V920EX CNC Vertical Lathe - Capable of performing powerful, heavy-duty cuts for turning the inside and outside of parts.

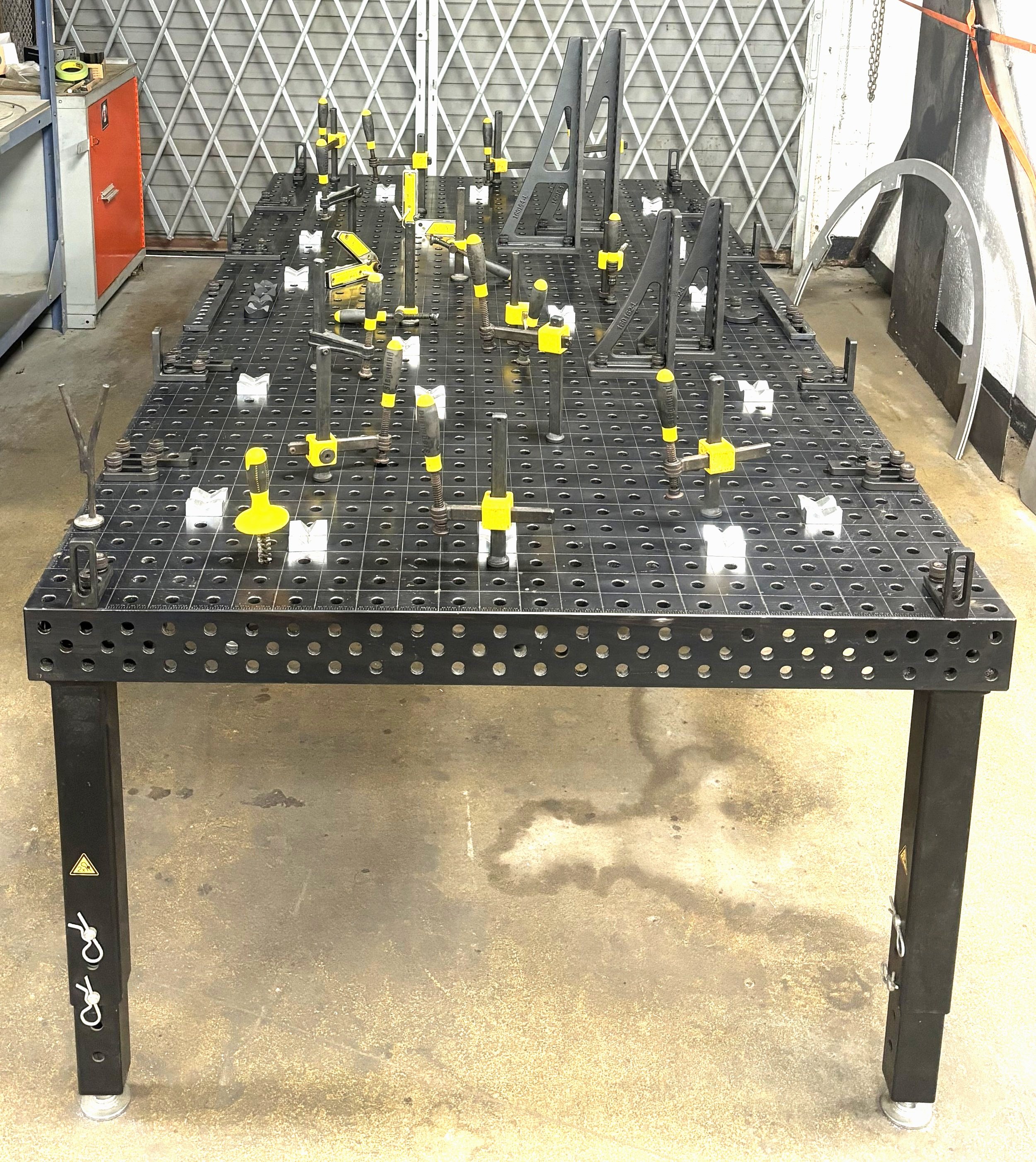

Siegmund Welding Table - 8'x 4' table with jigs, fixtures, and clamps for all types of welding needs.

Metal Working Capability:

12' shear capable of .5" thick aluminum

10' 60 ton brake with 500 dies

English Wheel for hand working dual contour surfaces in material up to .090" gauge thickness

16' Farnham Roller for forming double contour surfaces up to .063" gauge

Machine lathe (2)

Bridgeport machining centers (2)

MIG, TIG and Spot welding

Belt grinders

Bandsaws

Cutoff saws

Arbor presses

Metal Working Capability Expansion:

Vertical turret lathes

2 - 4 axis CNC mills

Faro arm - Platinum model

In-house test laboratory:

Tensile data acquisition using United Testing Systems model STM-100KN-E

Impact testing

Vacuum Chamber

Laboratory oven

Metal alloy identification and temper

Hardness tester

Material Coupon Moisture Conditioner

Balancing Capabilities

Hoffman Vertical 2 Plane Measurement

Well-engineered design combines a high-precision spindle with the consistency of a hard-bearing support system using piezoelectric transducers

6-Way Fully-Auto Mobile Console

Ovens:

12’ x 20’x 12’

10’ x 10’ x 8’

10’ x 10’ x 8’

6’ x 5’ x 5

2’ x 2’ x 2’

2’ x 2’ x 2’

10’ x 10’ x 10’

Stress Relieving Capabilities

Stand-Up 12 Way Power Console with Record (Stress Reliever) Power Consoles “Fully Automatic”

This Stress Reliever is used to relieve stress (locally) in metal after the welding process has taken place. This power console uses ceramic blankets capable of sustaining temperatures of 1200 + degrees. The Power Console gives us the capability to perform a number of different weld repairs on site.

Lean Manufacturing

Our Original Equipment Manufacturing department utilizes the benefits of Lean Manufacturing, such as Work Cells, Quality Process Charts Program, PCS Success “6 S”, and various other programs to create a smooth flow that shortens the lead time for delivery to customers.

PCS Success “6 S” Program : Sort, Straighten, Scrub, Systematize, Standardize, and Safety

Quality Process Charts Program tracks any turnbacks that prevent a specific process from moving smoothly. By using the QPC Program, we are able to correct any problems or snags throughout the manufacturing process which allows us to improve the quality of our parts, the manufacturing lead time, and the satisfaction of our customers.